PROJECT

Alkimos Desalination Plant

EQUIPMENT USED

Project Title:

Alkimos Desalination Plant

Project Type:

Water and Sewerage

Feature Summary:

PROBLEM

The project required accurate monitoring of the settlement changes in geotechnical layers during the pre-loading phase of the proposed ActiDAFF tank structure. Understanding these settlement changes was crucial to ensure the stability and integrity of the structure before construction.

SOLUTION

To address this challenge, the following equipment and methodologies were employed:

-

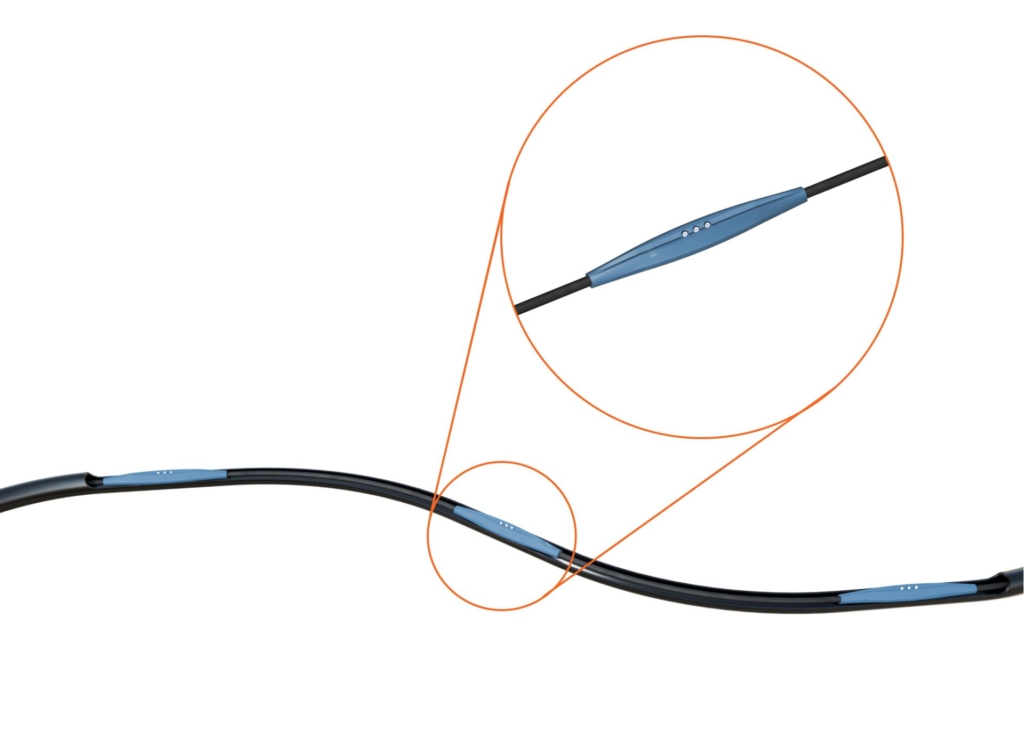

In-Place Extensometers (IPX):

In-Place Extensometers (IPX):

Multiple sensors were installed at designated geotechnical layers to depths of 25 meters. These sensors continuously monitored the settlement of individual layers, providing precise data on the movement and compression of the soil.

-

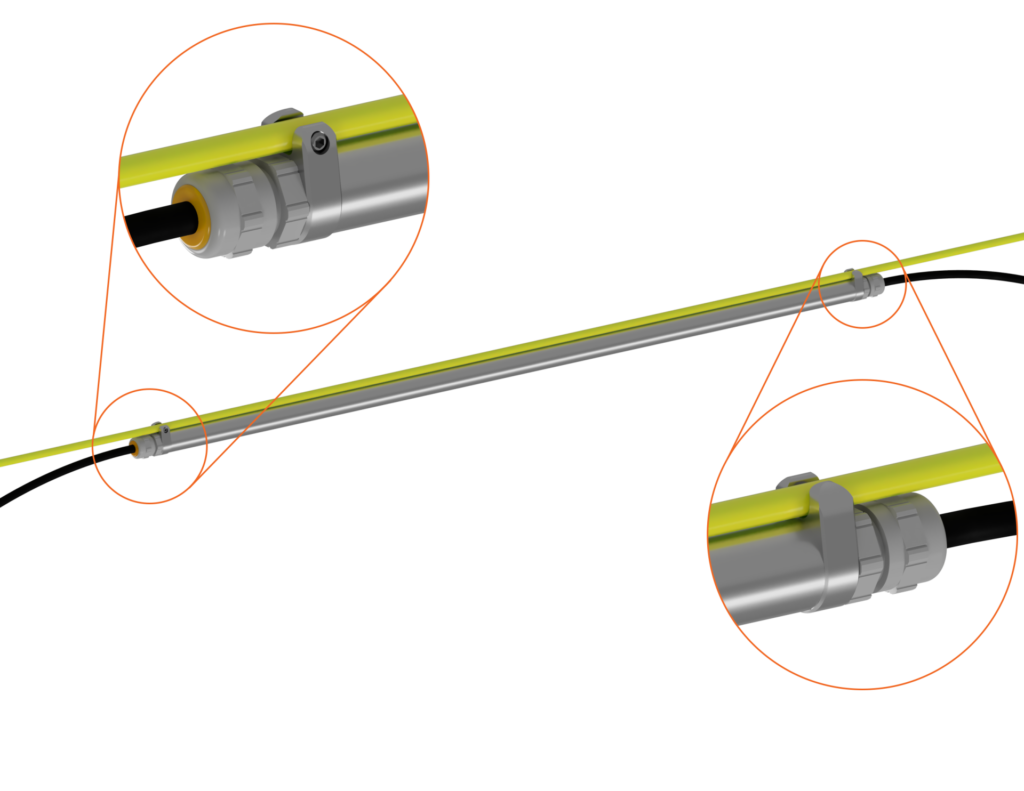

Automated Settlement Profiler (ASP):

Automated Settlement Profiler (ASP):

The ASP utilized a hydrostatic principle to deliver near real-time distributed settlement monitoring across the surface area before fill placement. This method ensured a comprehensive overview of settlement behavior over a large area, enabling timely adjustments and interventions.

-

Vibrating Wire Piezometer (VWP):

Vibrating Wire Piezometer (VWP):

Vibrating Wire Piezometers were installed at specified locations to monitor changes in pore water pressure within the pre-load area. This data was essential for understanding the relationship between settlement and pore pressure, which is critical for the stability of the soil layers.

RESULT

The implementation of these advanced geotechnical monitoring tools provided the project engineers with reliable and continuous data. As a result, they gained confidence in making informed decisions regarding the settlement process. The data indicated when the settlement of the pre-load area was slowing down and reaching completion. This timely and accurate information allowed for the construction commencement of the ActiDAFF tank structure to proceed with confidence, ensuring structural integrity and project success.

The use of IPX, ASP, and VWP technologies proved instrumental in achieving the project’s objectives, showcasing the importance of precise and real-time geotechnical monitoring in large-scale construction projects.

Monitel

Trust us to keep you informed about your construction, infrastructure, mining or rail assets.

Contact Us

Office Hours

Monday to Friday

7:00am to 5:00pm